Over the last two decades, I’ve built everything from boats to chicken coops to store displays, but above all else I prefer building gates. They’re outside (so I get to work in the sun while my sawdust blows away), and every one is unique, which keeps things intriguing. Since a front gate is one of the first things a homeowner (or guest) sees, each one has to look sharp, and vibe with the character of a home, in addition to working well. By working well, I mean that each has to function smoothly in daily use, when you’re carrying groceries inside, meeting friends and/or family, or trying to get stuff done — like yardwork, for example. Obviously, each also has to keep wanted kids and dogs in, and unwanted kids/dogs/strangers out.

Having repaired dozens of rickety gates that won’t open or close, or sag & drag, or are a nightmare to latch + lock, I’ve condensed what I know about gate construction:

“The Four Elements of a Good Gate”

1) An independent, non-sagging frame

Just as sheetrock doesn’t hold up the roof of a house (wall studs do), face boards shouldn’t support a gate. Those boards on the outside are decorative. It’s the skeleton underneath that ought to be doing the structural work. To keep from racking (the wobbly H effect), this frame should employ a diagonal strut, in compression — because wood is strongest that way. It ought to have braces, too — as attachment points for the face boards and latch, especially if it’s a big gate. Furthermore, the frame ought to be designed to minimize warping, so that those attractive face boards stay flat and flush.

2) Smooth rotation

For hinges to swivel smoothly, the plates on either side of the pins must be firm. That means strong anchors into a non-wobbly support post, and strong anchors into the gate’s frame — not merely its face boards. Whether you go with hinges or pintles & straps, they need to be long and strong, and you only need two.

3) Ground clearance

A gate should keep people out, and dogs in — and that’s it. It shouldn’t aspire to obstruct ants or mice. A gate with 1mm of ground clearance won’t impede insects or rodents anyway, and its dragging will detract from smooth rotation (and start to pull the hinges from the gate or the post) while frustrating everyone who tries to use it. Plus, what will you do when there’s snow, or ice, or a pebble on the ground? As a rule, I leave 3″ of space under gates.

4) The right latch

Most gate latches stink. But one style of gate latch is undeniably superior, on account of its one-handed usability, lockabilty, and reliability: when you throw the gate closed, it catches every time. (Many latches don’t do that — they just bounce the gate back.) This particular latch is uncomplicated (no wire/string/thumb-catch nonsense), durable, and even affordable… the one thing it lacks is adjustability, but I’ve designed a simple part that solves this — making it easy to move the latch up or down as the seasons demand without any tools. (More on this soon.)

** Other considerations **

*Interior stuff doesn’t work outside. I can’t overstate this one. It holds true for interior-style doors (with rails and stiles held together with glue and/or dowels), for recessed hinges, and for doorknobs and traditional spring latches. Trying to get away with a frameless gate, or itty-bitty hinges (whose tiny screws are always in tension), or a latch not designed to withstand the elements is asking for trouble.

*Use an appropriate wood. This seems so obvious, and yet bad handymen build gates out of the dumbest materials, even though the right materials are no mystery. Frames ought to be made of pressure-treated lumber, and (here in the arid West) face boards ought to be milled cedar (rather than flimsy pickets) or redwood. Both are light and rot-resistant. Latillas (used in Santa Fe’s “coyote” fences) are too heavy for gates. You shouldn’t need to support a gate with a training wheel.

*Employ the right fasteners. Duh again, and yet you wouldn’t believe what people (framers? bad handymen?) try to get away with. This means high-quality masonry screws, lag bolts, and framing screws (always star-drive), installed so that they’re in shear rather than tension, and so that they don’t invite water where you don’t want it. No nails is a hard rule; to attach face boards, I always use cabinet-head screws, so that wind and repeated vibration don’t loosen ’em.

*Weather protection. This one’s crucial, because doing it wrong (or not at all) will drastically shorten the lifespan of an otherwise-good exterior gate. Experience has taught me to avoid paint, and use a UV-resistant oil. Because oil penetrates into wood fibers, and doesn’t merely sit on top of them, it protects wood even if the surface gets dinged or scratched — which happens with gates. Paint, on the other hand, is basically a thin plastic bag — and traps water inside it, leading to rot. Plus, oil enhances the character of wood grain, which, glorious as it is, ought to be highlighted instead of hidden. And, it’s easy to maintain: just wipe on some more, without fussing about a precisely calibrated tint that has faded in the sun.

*Security. Though the latches I use are lockable, many customers want additional security via a deadbolt. Keyless (combination) deadbolts are awesome, but not 100% awesome, because most rely on batteries… which die quickly in the cold. There is, however, one keyless deadbolt — made in Japan — that’s entirely mechanical, beefy enough for exterior use, and elegant, too.

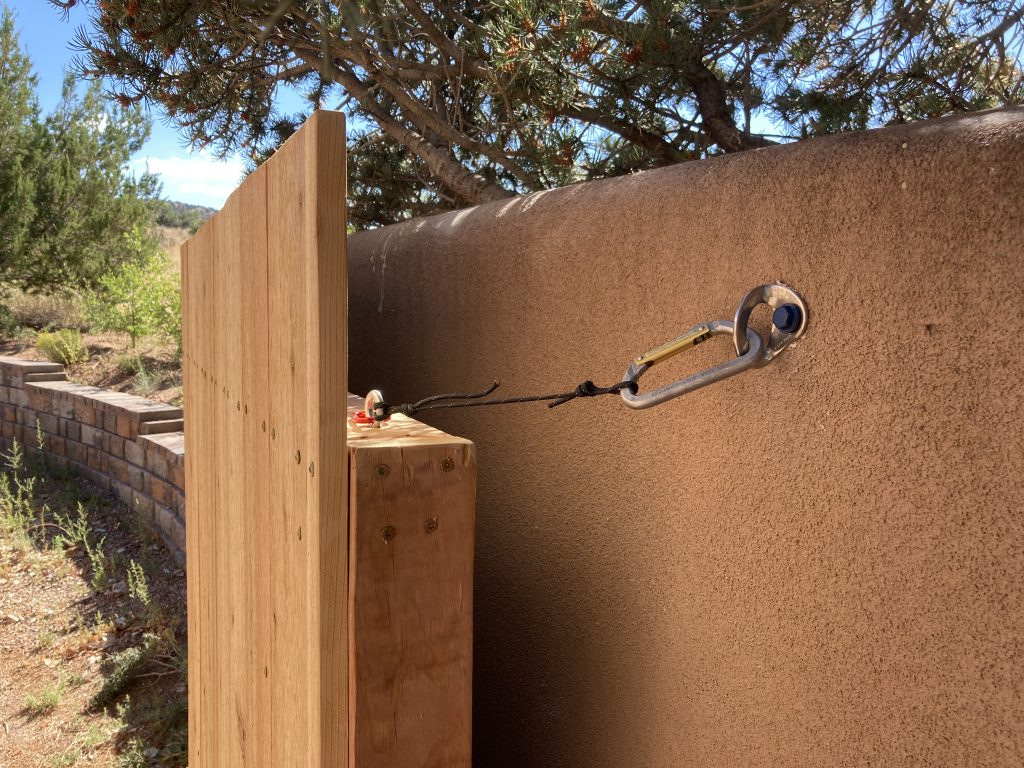

*Be wary of wind. You could do all of the above, and still ruin a gate by not defending against wind. A gate’s basically a big sail, and the wind out here is no joke! Propped open behind a rock, a gate may easily catch a gust and slam shut, damaging any number of parts. Big rocks may have worked OK for cavemen, but in the 21st century, bombproof climbing anchors and carabiners work a lot better, and look slick, too.

*Maintenance. Ain’t nuthin’ that don’t need maintaining, especially not outside. (I did, ehem ehem, author a book called Rust.) Plan on periodically giving your gate some attention, with a squirt of WD-40 in the hinges, some oil wiped on the face boards, and a quick seasonal latch adjustment, because wood moves with changes in temperature and humidity, just one more way it reveals its character.

And with that, some examples:

OTHER PROJECTS: timber-framed pergolas, decks, and inlaid address signs

(14′ x 16′ pergola, made of 8″ x 8″ posts, 6″ x 8″ beams, 4″ x 6″ rafters + braces, 1″ oak pegs, and custom recessed steel brackets.)

Custom address signs are available via Etsy.

How I work: I charge a fixed rate for labor, and — unlike many — won’t ask for payment until the job is complete. (Materials are on you.)

Email me: < jonnywaldman@gmail.com >